In an age where the demand for minerals and resources is ever-increasing, the mining industry supports modern civilization. From the precious metals that power our technology to the building materials that erect our cities, mining plays an indispensable role in our daily lives.

Yet, this age-old industry has challenges. Miners worldwide face complex safety regulations and efficiency and environmental stewardship issues. Traditional mining methods often involve risks to human lives, are labor-intensive, and are not always efficient in accessing hard-to-reach deposits. Additionally, there's a constant push to reduce the environmental footprint and adhere to increasingly stringent regulations.

Collaborative people building collaborative technology – that’s Exyn. We are pioneers in developing autonomous aerial robotic systems for complex environments. Our autonomy and mapping platform Nexys, is designed to benefit survey teams in GPS-denied environments. With a ruggedized tablet for easy mission planning and point cloud post-processing while underground, Nexys ensures that teams confirm they've captured the necessary data sets before returning to the surface, reducing the chances of costly rework and increasing efficiency.

Whether using drones for coal mining, drones for uncovering precious metals, or drones for geophysical mining, the benefits of drone mapping with Nexys go far beyond the typical understanding of drone technology. From our foundational expertise as a drone company to our adaptable solutions, Exyn Technologies stands at the forefront of autonomous mapping of underground mines, transforming how data is captured and utilized within the mining industry.

Read on to learn more about drones for mining applications and how this technology is revolutionizing the industry.

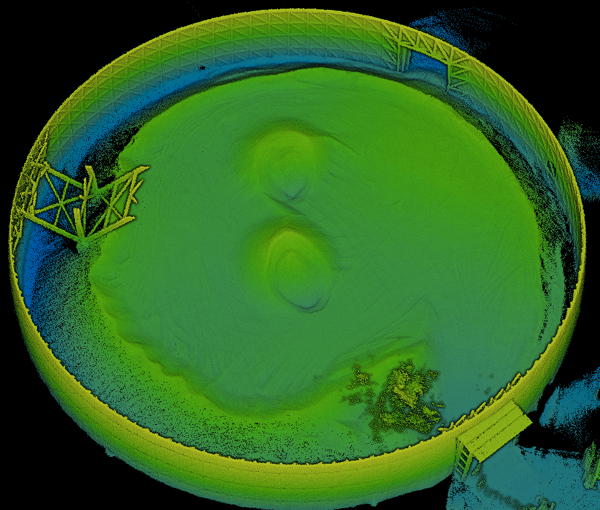

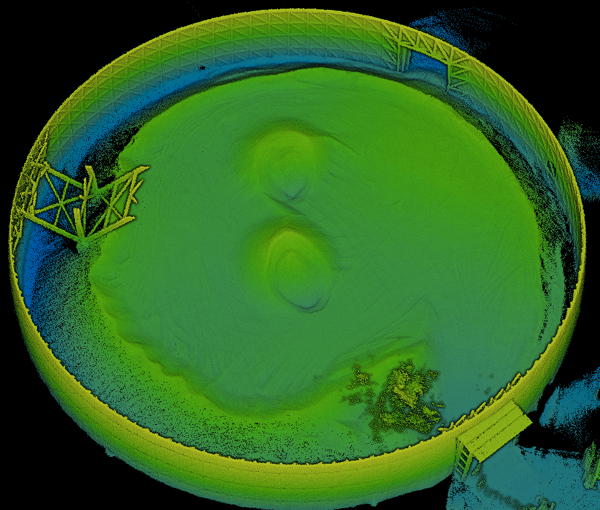

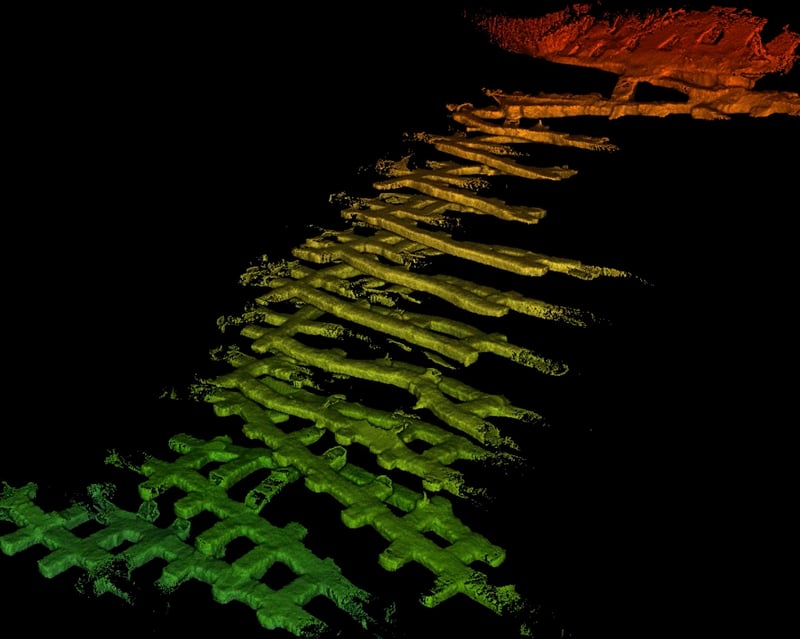

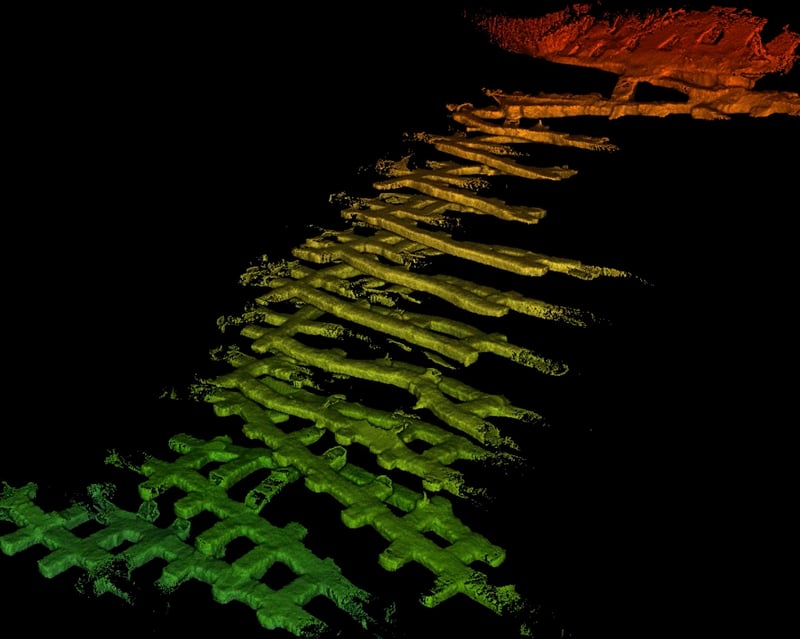

Surveying and mapping vast, inaccessible terrains has always been challenging. Mapping with an autonomous drone uses robotic airframes equipped with sophisticated sensors and a powerful SLAM algorithm to generate precise 3D point cloud maps in a fraction of the time it used to take, accelerating the planning process and providing a more comprehensive view of the available resources.

Monitoring the health of machinery and inspecting remote or dangerous areas of a mine site can be risky and time-consuming. Drones facilitate real-time monitoring and provide visual inspection without endangering human operators’ lives. Autonomous drones for inspection also significantly reduce downtime and associated costs by enabling predictive maintenance.

Worker safety remains paramount in the mining industry. A drone for mining will provide a new layer of protection by conducting surveillance in unstable or hazardous zones, delivering immediate data to support rapid response to emergencies. These devices are instrumental in creating a safer environment for workers by providing insights into potential risks.

Accurate measurement of stockpiles is vital for inventory control and financial reporting. Autonomous drones like the one's empowered through Nexys are equipped to measure volumes with pinpoint accuracy, replacing traditional methods that often result in errors. Automated and frequent stockpile measurements ensure that inventory data is always up-to-date and reliable.

Mine restoration is been quickly becoming more and more important in the mining industry. As sites get decommissioned, and operations cease, it becomes crucial to return these areas to a state that’s ecologically sound and sustainable. However, the post-mining phase isn't just about reclamation; it's also about the opportunity to identify leftover resources, ensuring that literally no stone remains unturned.

Drones now deploy to map and analyze mines that have long ceased operations to identify overlooked pockets of valuable resources. By providing a comprehensive and accurate view of the mine's layout and geology, surveyors can pinpoint areas where minerals, metals, or other resources are likely still present.

Surveying and mapping vast, inaccessible terrains has always been challenging. Mapping with an autonomous drone uses robotic airframes equipped with sophisticated sensors and a powerful SLAM algorithm to generate precise 3D point cloud maps in a fraction of the time it used to take, accelerating the planning process and providing a more comprehensive view of the available resources.

Monitoring the health of machinery and inspecting remote or dangerous areas of a mine site can be risky and time-consuming. Drones facilitate real-time monitoring and provide visual inspection without endangering human operators’ lives. Autonomous drones for inspection also significantly reduce downtime and associated costs by enabling predictive maintenance.

Worker safety remains paramount in the mining industry. A drone for mining will provide a new layer of protection by conducting surveillance in unstable or hazardous zones, delivering immediate data to support rapid response to emergencies. These devices are instrumental in creating a safer environment for workers by providing insights into potential risks.

Accurate measurement of stockpiles is vital for inventory control and financial reporting. Autonomous drones like the one's empowered through Nexys are equipped to measure volumes with pinpoint accuracy, replacing traditional methods that often result in errors. Automated and frequent stockpile measurements ensure that inventory data is always up-to-date and reliable.

Mine restoration is been quickly becoming more and more important in the mining industry. As sites get decommissioned, and operations cease, it becomes crucial to return these areas to a state that’s ecologically sound and sustainable. However, the post-mining phase isn't just about reclamation; it's also about the opportunity to identify leftover resources, ensuring that literally no stone remains unturned.

Drones now deploy to map and analyze mines that have long ceased operations to identify overlooked pockets of valuable resources. By providing a comprehensive and accurate view of the mine's layout and geology, surveyors can pinpoint areas where minerals, metals, or other resources are likely still present.

Stewart, British Columbia’s gold and silver mining experts, Ascot Resources, called in Exyn to use their autonomous aerial robots and drone-based mapping technology to help them determine remaining reserves in one of their oldest underground gold mines. The mine, closed since the 1940s, was inaccessible to humans but not Exyn’s drone-based mapping system technology.

Exyn’s drones require no prior knowledge of a site, no GPS, no specialized wireless infrastructure, and no pilot or communication with a ground control station, making exploration operations and mapping without human intervention entirely possible. This operation allowed the owners to conduct mineral exploration flights to make more accurate deposit predictions for investors, increasing financial returns and avoiding potential drawbacks of alternative methods.

Surveying with drones presents a significant opportunity for investors to extract every ounce of value from a mining site. With its possibility for high returns, autonomous drone technology is an attractive option that breathes new life into areas considered long exhausted.

Exyn’s drones have varying levels of autonomy and range from 1 to 5. Level 4A drones like Nexys are self-reliant for open-ended exploration and do not require human interaction during flight. At Level 4A Autonomy, Nexys freely explores complex spaces, with a complete determination of flight path at 2+ meter/second flight speeds and with higher quality data collection in larger volumes. In ideal conditions, Exyn’s drones can cover 16 million cubic meters – the equivalent of nine football stadiums – in a single flight. Advanced flight functions remove the need for human involvement, allowing workers to remain safe throughout drone surveying missions.

Traditionally, survey teams work to map open stopes from the berm, regarded as the most dangerous part of a mine, for several reasons:

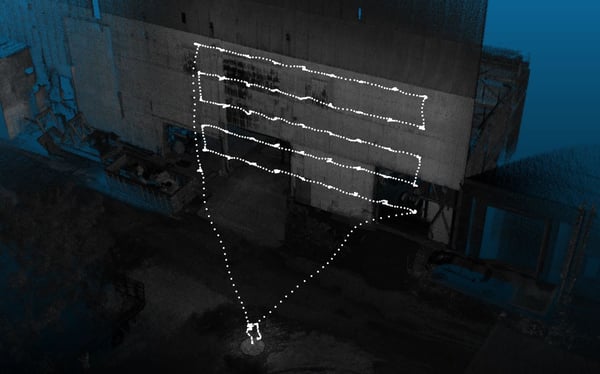

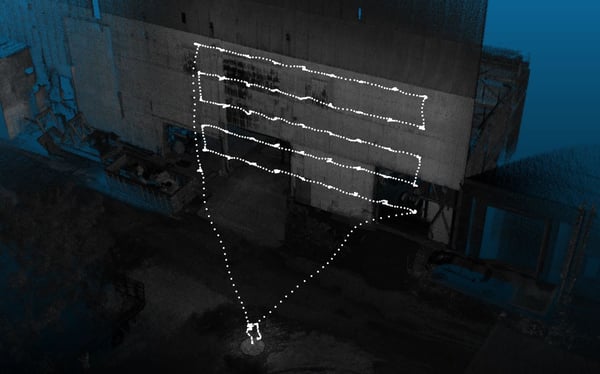

The danger associated with cave berms highlights the need for advanced monitoring techniques, such as those provided by specialized mining drones. 3D mapping drones like Nexys allow teams to safely stand 30 - 40 meters from that berm and fly the robot into the unknown cavity.

In addition to making it easier to map unexplored areas, autonomous drone data provides real-time information on cave stability and condition and significantly reduces the risks associated with manual inspections.

Convergence monitoring involves observing and measuring the movement or deformation of the walls, roof, or other structural elements within a mine. This movement signals potential stability issues, particularly in underground mines where pressure from surrounding rock leads to shifts and changes.

Some areas may be challenging to reach for conventional manual measurements, especially if they show instability. In addition, understanding what the measurements mean, especially in real-time, requires expertise and sometimes sophisticated modeling.

Convergence monitoring in mining is a vital aspect of modern mining operations. By understanding how the mine behaves and responds to ongoing extraction, mining companies better maintain safety, optimize their operations, and predict issues before they become significant problems. Technologies like autonomous drones enhance this monitoring, providing new ways to gather and interpret essential data.

By incorporating technology like drones, mining operations further enhance safety protocols, protect workers, and maintain the structural integrity of the mining environment.

Exyn’s drones have varying levels of autonomy and range from 1 to 5. Level 4A drones like Nexys are self-reliant for open-ended exploration and do not require human interaction during flight. At Level 4A Autonomy, Nexys freely explores complex spaces, with a complete determination of flight path at 2+ meter/second flight speeds and with higher quality data collection in larger volumes. In ideal conditions, Exyn’s drones can cover 16 million cubic meters – the equivalent of nine football stadiums – in a single flight. Advanced flight functions remove the need for human involvement, allowing workers to remain safe throughout drone surveying missions.

Traditionally, survey teams work to map open stopes from the berm, regarded as the most dangerous part of a mine, for several reasons:

The danger associated with cave berms highlights the need for advanced monitoring techniques, such as those provided by specialized mining drones. 3D mapping drones like Nexys allow teams to safely stand 30 - 40 meters from that berm and fly the robot into the unknown cavity.

In addition to making it easier to map unexplored areas, autonomous drone data provides real-time information on cave stability and condition and significantly reduces the risks associated with manual inspections.

Convergence monitoring involves observing and measuring the movement or deformation of the walls, roof, or other structural elements within a mine. This movement signals potential stability issues, particularly in underground mines where pressure from surrounding rock leads to shifts and changes.

Some areas may be challenging to reach for conventional manual measurements, especially if they show instability. In addition, understanding what the measurements mean, especially in real-time, requires expertise and sometimes sophisticated modeling.

Convergence monitoring in mining is a vital aspect of modern mining operations. By understanding how the mine behaves and responds to ongoing extraction, mining companies better maintain safety, optimize their operations, and predict issues before they become significant problems. Technologies like autonomous drones enhance this monitoring, providing new ways to gather and interpret essential data.

By incorporating technology like drones, mining operations further enhance safety protocols, protect workers, and maintain the structural integrity of the mining environment.

In the mining industry, time is of the essence. The faster you access critical information, the more efficient and effective your operations become. With the integration of drone technology, the industry is witnessing a new era where speed is a necessity. Here's a look at how mining drone technology is revolutionizing the industry:

Drones easily maneuver into areas that would be challenging or impossible for humans or traditional surveying equipment to access. Whether it's a narrow cavity, a steep slope, or a hazardous site, a mining UAV (Unmanned Aerial Vehicle) can reach it. By accessing these hard-to-reach areas, underground mine drones ensure the data collected is complete and accurate. No longer are there 'blind spots' in the information that might lead to mistakes or missed opportunities.

Drones equipped with advanced sensors and cameras cover large areas in a fraction of the time required for manual surveying. A task that might take days or even weeks can be completed in just hours. The speed of commercial drones for mining allows data to be collected more frequently. This regular updating leads to more up-to-date and accurate maps, essential for real-time decision-making and long-term planning.

Drones equipped with LiDAR capture environments from multiple angles and elevations, which traditional 2D mapping technologies struggle with. Drones used for mining create accurate 3D models of the site by compiling these multi-angle images. These models provide a comprehensive view of the terrain and structures, allowing for precise planning, monitoring, and analysis.

The shift from 2D to 3D isn't just a technological upgrade; it's a fundamental change in how mining operations understand and interact with their environment. Whether it's predicting how a new excavation will affect stability or planning the most efficient route for machinery, 3D modeling offers insights that 2D simply cannot provide.

Implementing UAVs for mining translates into significant cost savings for mining companies. By reducing the need for human intervention in hazardous or remote locations, drones minimize the risk to personnel and the associated safety costs. Automating tasks such as surveying, inspection, and monitoring allows for a more streamlined workflow, reducing labor expenses and shortening project timelines, cutting operational costs for mines and potential sites.

At Exyn, we design state-of-the-art drones to integrate seamlessly into your existing operations, providing an efficient solution that aligns with your budget. A mine drone transforms the financial landscape of the mining industry by providing a cost-effective solution to several challenges:

Integrating drones into mining practices is vital to modernization, improving safety, efficiency, data accuracy, and cost-effectiveness. As the industry continues to evolve, drones are proving to be indispensable tools, setting new standards for excellence and innovation.

Download Now

At Exyn Technologies, we're not just a company that understands the intersection of drones and artificial intelligence. Our core identity stems from our deep expertise in creating world-class autonomous systems. We're not merely a mapping company that needs to grapple with drone technology; we're innovators who capture high-value data from dangerous environments.

As we venture into a world increasingly dependent on a waning amount of minerals and resources, there's no denying that traditional mining methods face growing challenges. Drones, like the type provided by Exyn Technologies, are not just enhancing the mining industry — they're revolutionizing it. From unprecedented levels of safety to unparalleled efficiency, the era of drone integration in mining is upon us. For those seeking to stay ahead of the curve, it's time to look skyward and embrace the future. Ready to explore? We are ready to help you find the best drones for mining, and we invite you to book a demo to experience the Exyn advantage firsthand.